Raw material storage, dosing, and mixing

Sand lime bricks consist of the two raw materials sand and lime only. For the manufacturing process, water is required in addition. The raw materials that are mostly supplied from local extraction places are stored separately in raw material silos. On the way to the silos, the sand passes a screening station to separate oversize material.

Masa sand lime brick making plants are designed to use at least two different types of sand. The advantage for the customers is that the product quality can directly be influenced by a specific mixture of the different types of sand.

The raw materials sand, lime, and water are exactly dosed and weighed in individual scales and fed into the intensive mixer. In the mixing process, a homogeneous and highly disperse sand lime compound is generated.

The complete automatic process is controlled and monitored via the Masa mixing plant control system .

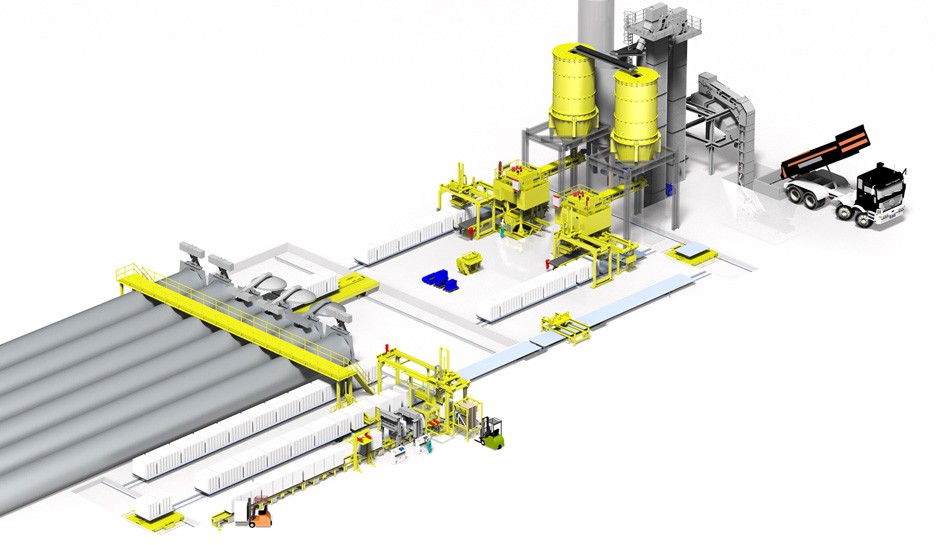

It's a long way from raw materials through the mixture to the finished stone. Many plant components are involved in this process. Only if the system components are matched, can one be assured of a smooth process and economical operation of the block making plant.

It's a long way from raw materials through the mixture to the finished stone. Many plant components are involved in this process. Only if the system components are matched, can one be assured of a smooth process and economical operation of the block making plant.

The manufacturing of autoclaved aerated concrete products demands high standards for mixing and dosing of the aggregates, the control of the fermentation process and the control of each production step. Masa's aerated concrete installations are proven advanced technology processes, designed according to customers specific requirements. This approach allows complete solutions to ensure highly efficient, optimised processes resulting in consistent final product quality.

The manufacturing of autoclaved aerated concrete products demands high standards for mixing and dosing of the aggregates, the control of the fermentation process and the control of each production step. Masa's aerated concrete installations are proven advanced technology processes, designed according to customers specific requirements. This approach allows complete solutions to ensure highly efficient, optimised processes resulting in consistent final product quality.

It's a long way from raw materials through the mixture to the finished sand lime bricks. Many plant components are involved in this process. Only if the system components are matched, can one be assured of a smooth process and economical operation of the sand lime brick production plant.

It's a long way from raw materials through the mixture to the finished sand lime bricks. Many plant components are involved in this process. Only if the system components are matched, can one be assured of a smooth process and economical operation of the sand lime brick production plant.

It's a long way from raw materials over mixture to the finished (Kerb)stone. Masa Kerbstone presses were developed to fulfill among other criteria, the special requirements of the "British Standard" kerbstones. This "British Standard" is still a condition in countries of the Middle East and the UK.

It's a long way from raw materials over mixture to the finished (Kerb)stone. Masa Kerbstone presses were developed to fulfill among other criteria, the special requirements of the "British Standard" kerbstones. This "British Standard" is still a condition in countries of the Middle East and the UK.

Masa plants and machines are installed and commissioned by our own experienced fitters. Masa relies on qualified personnel, trained in Germany.

Masa plants and machines are installed and commissioned by our own experienced fitters. Masa relies on qualified personnel, trained in Germany.

The Masa Lifetime service extends far beyond the actual assembly and commissioning of a plant. Masa can rely on specific know-how and an industry experience of more than 110 years.

The Masa Lifetime service extends far beyond the actual assembly and commissioning of a plant. Masa can rely on specific know-how and an industry experience of more than 110 years.

Do you need support with your machine? Masa Support scores in both quality and significantly improved accessibility. Whether "first aid" for technical problems, updates, functional expansions of your production plant or technical questions, the know-how provided by Masa Support covers a wide range of services.

Do you need support with your machine? Masa Support scores in both quality and significantly improved accessibility. Whether "first aid" for technical problems, updates, functional expansions of your production plant or technical questions, the know-how provided by Masa Support covers a wide range of services.

One of the keys to increasing productivity and quality is continuous training of the machine and maintenance personnel.

One of the keys to increasing productivity and quality is continuous training of the machine and maintenance personnel. Are you looking for your contact? The Masa Service team introduces itself.

Are you looking for your contact? The Masa Service team introduces itself.